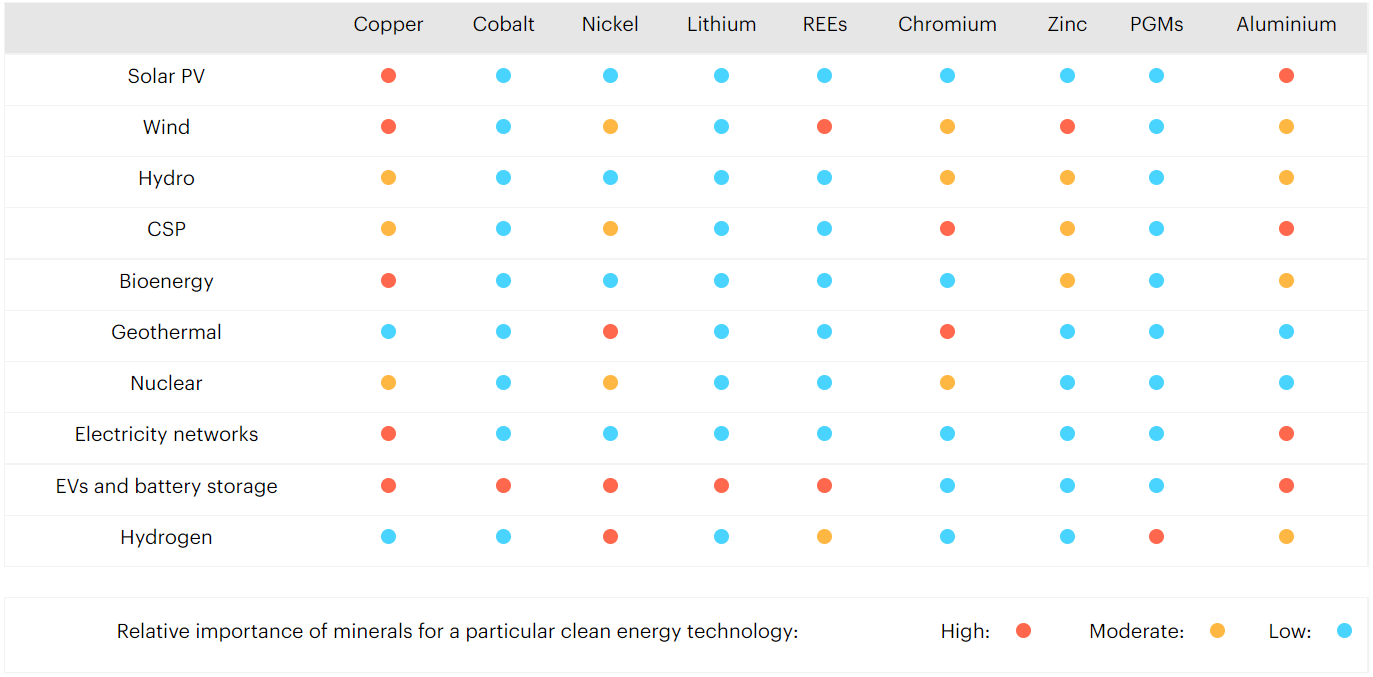

As we race towards deploying clean energy technologies at scale, demand for critical minerals — the enabling building blocks for many of these solutions — is growing exponentially.

While traditional energy sources, including coal and natural gas plants, as well as conventional cars are heavy pollutants, they also demand significantly less minerals than many clean energy alternatives. Electric vehicles and their batteries are the most obvious example here, with EV’s using six times as many minerals than an internal combustion engine (ICE) vehicle.

But it’s not only EVs. The same applies to other renewable energy solutions, including solar plants, wind farms, and electrolyzers used in hydrogen production. Consequently, demand forecasts for different metals essential to clean technologies are almost frightening to read. Lithium, for example, based on IEA’s Sustainable Development Scenario, will experience a 42-fold increase in demand by 2040, compared to 2020.

For nickel and cobalt, two other important metals in the energy transition, the demand is expected to grow 20-fold. According to Benchmark Minerals, more than 300 new mines are needed by 2035 to meet the demand generated by batteries alone. In terms of needed investments, we are talking about hundreds of billions — even trillions — of dollars. And mining is only the first step of a long value chain.

Security of critical mineral supply

As if the rapid growth in demand is not challenging enough alone, the US has more recently awakened to a new aspect of this conundrum — security of supply.

Just as the security of oil supply has been an essential issue of global geopolitics since the early 1900s, we are starting to see a similar trend in the world of mineral supply.

The importance of critical minerals has been clear for a while, yet geopolitical tensions over the last few years have elevated this topic to a new level of urgency.

Over the last three years, Covid-19 caused unprecedented stress on global supply chains of all kinds. This year, the war in Ukraine brought to light the grim realities of trade with Russia — one of the largest nickel producers in the world. Meanwhile, reports of human rights abuses at the Congolese cobalt mines (responsible for 70% of global supply) have raised questions on how to source cobalt sustainably. In Chile and Peru, political instability and talks of nationalization of lithium and copper mines are casting shadows over mining companies operating in the area.

And finally, the increasingly strained relationship between the US and China has brought dark clouds over the supply of nearly all major minerals, battery components, and even battery production equipment. Thus, the ideal of global free trade has taken a step or two back in light of this not-so-pretty reality.

With demand surging at an unprecedented speed, and critical mineral supply under increasing pressure, these compounding conditions are painting a challenging bigger picture.

Recent legislation accelerating the battery industry’s growth

In better news, both the government and private sector are seeing and responding to this challenge. The Inflation Reduction Act, specifically, tackles this issue from two sides.

First, EV passenger vehicles are eligible for $7,500 in tax credits, but only if a certain share of the battery materials and components are sourced from the US or allied countries. Not only that, the use of Chinese and Russian minerals or components in EV battery production is banned altogether — if you want to get the tax credit.

The legislation gives automotive OEMs a new and strong incentive to restructure their supply chains to meet these requirements, which is likely to create a seller’s market for existing and upcoming US material and component producers.

Secondly, the full battery value chain is also now supported by generous production tax credits outlined in IRA — 10% of the cost of producing battery minerals and materials and $35 per KWh of battery cell capacity. In addition to IRA, another recent piece of legislation, the Bipartisan Infrastructure Law, is steering more than $7 billion to battery production projects in the US. Startups such as Ascend Elements and Lilac Solutions have been among the major beneficiaries of the program, receiving tens to hundreds of millions in grants.

Such a large-scale government initiative has now evoked noteworthy responses from the private sector, which is looking to ride the tailwinds of this monumental public sector action. In the first three months following IRA’s passing in August, over $13 billion of investments have been announced, nearly double the volume of investments compared to the same three month time period prior to August. And, more is likely to follow as larger investments take time to prepare.

Areas for innovation and investment along the battery value chain

Specific areas of the battery and metal value chain pose a particular challenge for current onshoring ambitions. This is especially apparent in the up and midstream areas, which are heavily concentrated in China and other countries of concern. Investments into these specific areas are crucial.

Growing local production capacity with conventional methods is one way to bolster this part of the value chain. However, these bottlenecks also present attractive areas where technological innovations can help ease the pressure — and provide potentially attractive returns for investors.

Taking a closer look at the value chain, let’s explore four potentially disruptive opportunities along it.

1. Mining

Mining is the first step in the value chain. But building an operating mine is a product of years — often a decade — of work. Meaning, that today’s actions won’t materialize impact in a short time frame. Because of this, the US will likely rely heavily on its free trade partners with bigger mining muscles, such as Australia, Canada, and Chile, but in the longer term, local production will need to grow too.

Besides the lengthy process, there are many hurdles mining projects need to cross. Naming just two, a less than 1% success rate of the exploration phase, and vast environmental issues including excessive use of water in lithium mines. We are now seeing an increasing number of startups addressing these challenges with novel offerings, for example, using machine learning-powered exploration tools to provide significant improvements in accuracy and more environmentally friendly lithium extraction technologies.

2. Metal refining

One step down the value chain is metal refining. China currently dominates this sector, representing a 68% share of global nickel refining and 73% of cobalt. In rare earth elements, the number is close to 90%.

In the US, the industry is nearly non-existent. And again, in addition to the need for onshoring and friend-shoring, the scale of production has to grow manyfold. On a positive note, compared to developing a new mine, setting up a processing facility is a more rapid process. Namely, this can help to bring faster relief to automotive OEMs striving to meet the IRA’s requirement of minerals needing to be extracted or processed in the US, or through a free trade partner.

3. Components and batteries

On the battery component side, the situation is (once again) grim. Benchmark Minerals forecasts that by 2030, cathode and anode production in North America will only be able to fulfill less than 4% of the domestic demand. Heavy investment is needed and is likely a reason we have begun seeing first movers here, both among incumbents and with startups. LG Chem, for example, just announced that it will invest over 3 billion to build a cathode manufacturing plant in Tennessee, while Mitra Chem — a startup utilizing machine learning to speed up their R&D — is aiming to be the first US-based large-scale LFP cathode producer. Despite these few promising initiatives, the overall outlook is still alarming.

The US cell manufacturing industry, on the other hand, appears to be picking up speed and meeting IRA’s component requirements. Tesla and Panasonic, for example, already operate large-scale production in the US, while other automotive OEMs and startups like ONE and Freyr have recently announced plans to build their own plants.

4. Recycling

Recycling is the last part of the battery value chain. However, as the output of the recycling process will be fed back to the refineries and battery component producers, it can also be thought of as a new beginning of the value chain. The limited feedstock of production scrap and end-of-life batteries means that recycling alone will not ease the supply and demand mismatch. Still, its role is destined to grow.

Northvolt, one of the leading battery manufacturers in Europe, has stated a goal to have 50% of the raw materials they use be sourced from recycled materials by 2030. Pyrometallurgy and hydrometallurgy are currently dominating technologies, but startups are bringing to market alternative solutions such as electro-extraction (Nth Cycle) and various direct recycling processes (such as PNE) that hold promises of lower costs and lower CO2 emissions.

Not all quiet on the Western front

It’s not an overstatement to say that securing the needed materials for the clean transition is one of the great industrial challenges of our age.

Luckily, as we have seen, it’s not all quiet on the Western front. We are still deep in the woods, but there are encouraging new signs of activity from startups and investors, as well as incumbents and governments.

What remains to be seen is whether new innovations, investments, the increasing role of recycling, and the eventually flattening demand growth rate, will add up to make today’s supply crunch a transient phenomenon — or if it turns out to be a more permanent problem.

The harsh truth is that the larger the supply-demand gap gets, and the longer it takes to solve it, the bigger the effect will be on the success of our clean energy transition.

Please reach out to our investment team at hello@valoventures.org if you are building a company within the critical minerals value chain.